Produce your own nitrogen on site and become your own supplier

Nitrogen is a gas widely used in laser cutting for its inert properties that prevent any reaction with the molten metal. It is traditionally supplied to industrial sites by trucks, and stored in high pressure cylinders or cryogenic tanks.

Request for information

This method of supply is expensive, polluting and generates constraints and risks for users. However, there are solutions to produce nitrogen on site by generator. This simple process, whose efficiency has been demonstrated, has many advantages.

Download the product datasheet

Why produce nitrogen on site?

- Autonomy / security of supply

- No logistic constraints

- Continuous production

- Cost reduction

- Increased safety

- Optimal cutting quality

NOVAIR's nitrogen production solutions for laser cutting

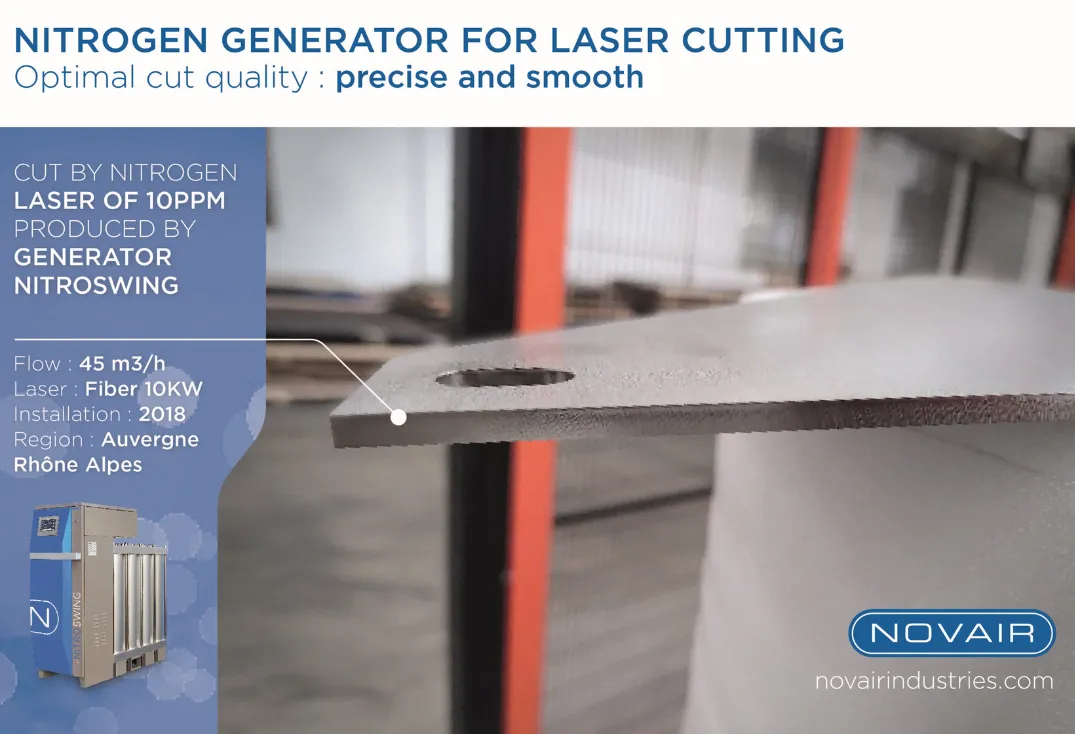

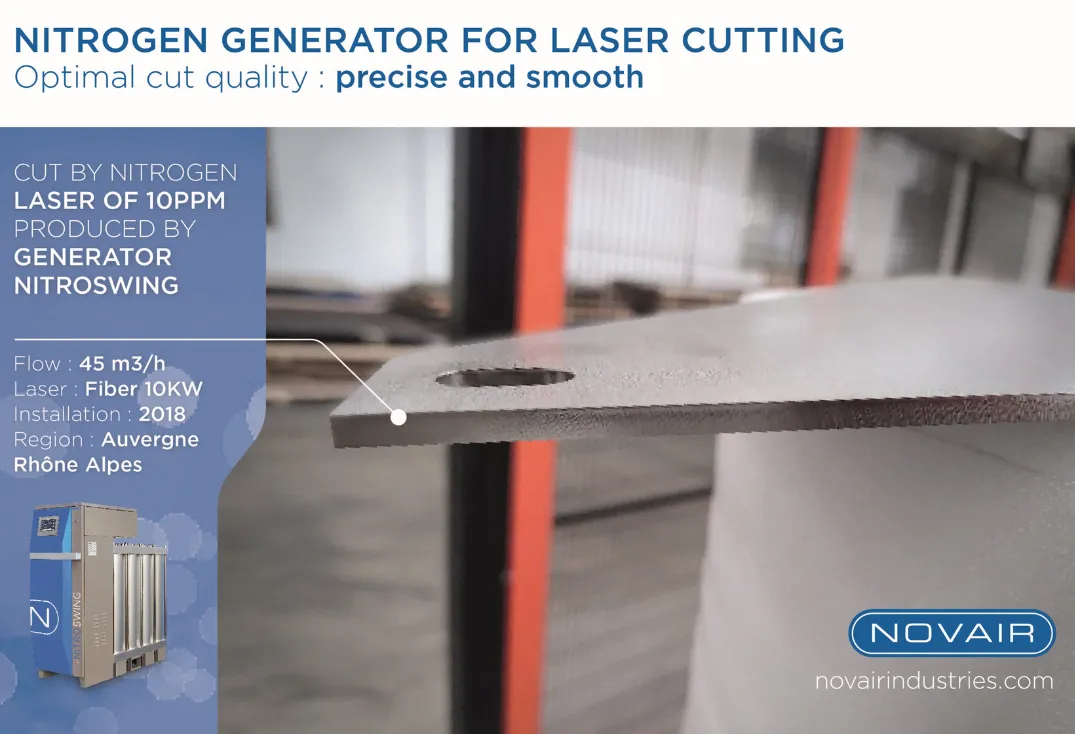

For the laser cutting industry, NOVAIR has designed NITROSWING LASERPACK, an innovative nitrogen production and on-site cylinder filling solution capable of supplying all types of laser, fiber or CO2 machines. This solution allows a continuous and autonomous supply of nitrogen according to the specifications required by the cutting machines.

Bateo, a company specialized in locksmithing and precision metalwork, uses a NOVAIR on-site nitrogen production solution to supply its latest generation fiber laser. Totally convinced, the company manager applauds the simplicity of the process and the independence gained for its gas supply, as well as the savings made. Not to mention the ecological aspect of the solution, which avoids recurring gas deliveries and the associated CO2 emissions.

In the Press

Discover the latest article on NOVAIR's solutions for laser cutting published in Metal Interface.

NOVAIR also offers solutions for :

- Welding and cutting

- Heat treatment of ferrous and non-ferrous materials

- Oxycutting

- Oxycombustion: This technique involves replacing the ambient air used in combustion with a mixture of oxygen and nitrogen or another gas, to power industrial furnaces. Oxycombustion improves energy efficiency, reduces NOx emissions and enables higher flame temperatures. NOVAIR nitrogen generators provide a reliable, continuous supply for these demanding processes.

What are the advantages of oxycombustion for furnaces?

- Higher flame temperatures: Pure oxygen promotes faster, more intense combustion, enabling higher temperatures to be achieved than with air.

- Lower flue gas volumes: By eliminating the nitrogen naturally present in air (78%), oxycombustion generates fewer flue gases, simplifying their treatment and reducing heat loss.

- Improved energy efficiency: Less heat is dissipated in the exhaust gases, improving overall furnace efficiency.

- Reduced pollutant emissions: Oxycombustion significantly reduces NOx emissions, often produced by the interaction of nitrogen in the air with oxygen at high temperatures.

- Better control of chemical reactions: The use of purified nitrogen enables control of the furnace atmosphere, avoiding undesirable reactions with the materials being treated (oxidation, decarburization, etc.).